A steam engine works by heating water in a boiler until it creates high-pressure steam, which then pushes a piston back and forth. This reciprocating motion is transformed into rotary movement using a crankshaft, powering machines or vehicles. Valves control when steam enters and exits, ensuring smooth operation. The entire process converts heat energy into useful mechanical work. To understand the detailed steps and how all parts work together, keep exploring the fascinating mechanics behind steam power.

Key Takeaways

- Heat from fuel heats water in a boiler, producing high-pressure steam.

- Steam is directed to push pistons, converting thermal energy into mechanical reciprocating motion.

- Valves control steam admission and exhaust, synchronized with piston movement for continuous operation.

- Piston movement is transferred to a crankshaft, converting reciprocating motion into rotary power.

- The rotary motion drives machinery, locomotives, or generators, producing useful mechanical or electrical energy.

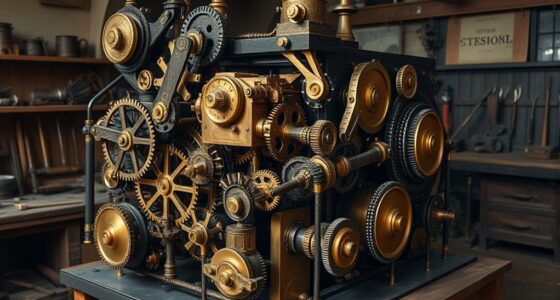

Steam engines convert heat energy into mechanical work by using boiling water to create steam, which then powers moving parts. When you operate a steam engine, the first step involves generating steam in a boiler. The boiler design is essential because it determines how efficiently heat is transferred to the water, how quickly the steam is produced, and how safe the system remains. A well-designed boiler ensures that water reaches the necessary pressure and temperature without risking overpressure or leaks. Inside the boiler, fuel such as coal, wood, or oil heats water until it boils, producing high-pressure steam that is channeled into the engine’s cylinder.

Once the steam is generated, it enters the piston mechanism. This part of the engine converts the energy of the steam into mechanical movement. The piston mechanism works by allowing the high-pressure steam to push a piston back and forth within a cylinder. As the steam enters one side of the piston, it exerts force, pushing the piston in a specific direction. When the piston reaches the end of its stroke, valves open to release the spent steam and allow fresh steam to enter, maintaining a continuous cycle. This process transforms the pressure of the steam into reciprocating motion, which can be harnessed to do work.

Steam pushes the piston back and forth, transforming pressure into useful reciprocating motion.

You’ll find that the design of the piston mechanism is essential for efficient operation. The piston must fit snugly within the cylinder to prevent steam leakage, which would reduce power and efficiency. The connecting rods attached to the piston transfer the reciprocating motion into rotary motion, often turning a wheel or driving machinery. The timing of valve movements and steam admission is synchronized with piston movement, ensuring smooth operation. This synchronization is typically achieved through a system of linkages and timing mechanisms, which control when steam enters and exits the cylinder.

As you observe the engine in action, you’ll notice that the piston’s back-and-forth motion is converted into rotary motion via a crankshaft connected to the piston mechanism. This rotary motion can then power a variety of machines, from locomotives to factory equipment. The entire process relies heavily on the interplay between boiler design and piston mechanism. An optimized boiler produces a steady, high-pressure steam, while a well-constructed piston mechanism ensures that this steam’s energy is effectively transformed into useful work. Together, these components make steam engines reliable, efficient sources of mechanical power, revolutionizing industry and transportation during their heyday.

Frequently Asked Questions

How Has Steam Engine Technology Evolved Over Time?

You see, the historical development of steam engine technology has advanced considerably through technological innovations. Early models like Thomas Newcomen’s engine gave way to James Watt’s improvements, boosting efficiency and power. Over time, you’ve witnessed the shift from simple beam engines to more compact, powerful designs. These innovations fueled the Industrial Revolution, transforming transportation and industry. Today, modern steam turbines continue this legacy, showcasing ongoing evolution in steam engine technology.

What Are the Environmental Impacts of Steam Engines Today?

You might think steam engines are ancient history, but they still leave a mark. Today, their environmental impacts include significant carbon emissions and water usage, ironically contributing to pollution even as they fade away. While modern engines are cleaner, those old steam-powered relics caused water depletion and released greenhouse gases. So, next time you see a steam engine, remember it’s a reminder of how past technology still affects our planet today.

Can Steam Engines Be Used for Modern Renewable Energy Sources?

You can use steam engines for modern renewable energy by harnessing biomass turbines and geothermal steam. Biomass turbines convert organic material into heat, producing steam to generate electricity, while geothermal steam taps into Earth’s heat sources. These methods are sustainable, environmentally friendly, and help reduce reliance on fossil fuels. By integrating steam engines with renewable sources, you create cleaner energy options that benefit both the environment and energy efficiency.

What Safety Measures Are Essential When Operating Steam Engines?

Safety is your shield when operating steam engines. You must always check pressure valves to prevent dangerous overpressure, symbolizing control over chaos. Regular boiler inspections act as vigilant guardians, catching potential issues early. Wear protective gear and keep clear of moving parts, ensuring you respect the immense power at play. These measures safeguard you and the machinery, transforming raw energy into a safe, reliable force that keeps your operation running smoothly.

How Do Steam Engines Compare to Internal Combustion Engines Efficiency-Wise?

You’ll find that steam engine efficiency generally lags behind internal combustion engines. Steam engines convert heat into work, but they often lose more energy through heat and friction. In comparison, internal combustion engines are more efficient because they burn fuel directly inside cylinders, extracting more energy. So, if you’re comparing efficiency, internal combustion engines usually outperform steam engines, making them preferable for most modern applications.

Conclusion

Now that you know how steam engines work, picture yourself as a conductor guiding a powerful orchestra. Just like the rising steam builds pressure to move the piston, your passion fuels progress. Remember, the first steam engine powered the Industrial Revolution, transforming society much like a spark ignites a fire. With this knowledge, you hold the key to understanding how harnessing steam changed the world—proof that even small ideas can create monumental change.