Spring-powered mechanisms have transformed clockwork devices beyond traditional steam engines by harnessing mechanical energy for precise, durable operation. You’ll find them in mechanical watches, where tiny springs store energy to keep time accurately, and in toys that come to life through wound-up springs. These simple yet clever systems continue to inspire innovations in wearable tech, medical devices, and sensors. If you explore further, you’ll discover how these elegant solutions shape modern technology’s future.

Key Takeaways

- Springs enable precise, battery-free operation in modern clockwork devices like mechanical watches and timers.

- Mechanical toys utilize wound springs to animate figures, showcasing spring technology beyond steam engines.

- Advances in miniaturized spring mechanisms enhance wearable tech, medical devices, and autonomous sensors.

- Springs provide durable, energy-efficient solutions in devices where electronic dependency is limited or undesirable.

- Their simple yet resilient design continues to inspire innovative clockwork and mechanical innovations today.

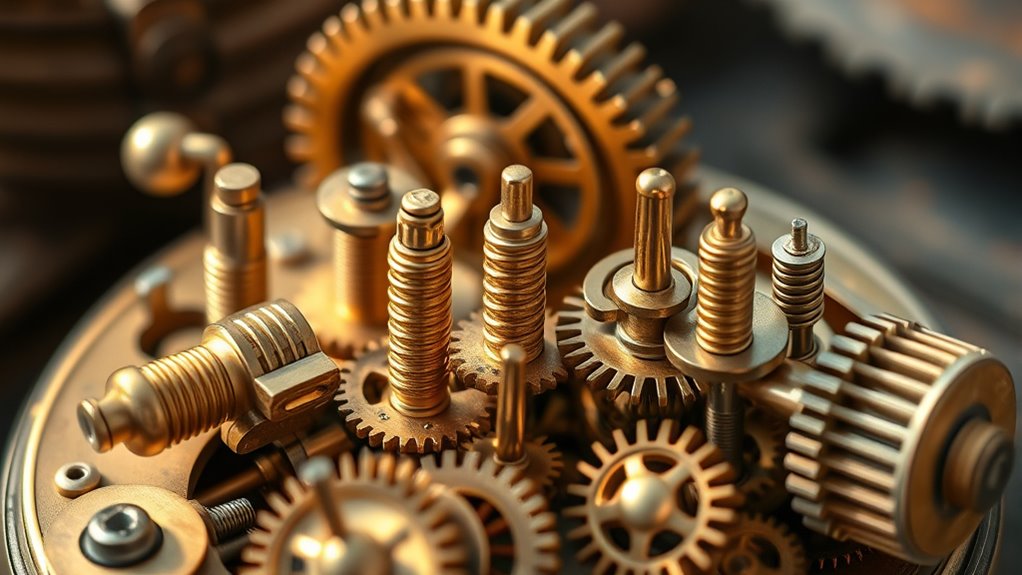

Have you ever wondered how traditional springs are shaping the future of technology? These small, resilient components have been around for centuries, powering everything from clocks to mechanical toys, and now they’re making a surprising comeback in modern innovations. Springs, especially in the form of miniature timepieces, demonstrate that simple mechanical systems can achieve extraordinary precision, durability, and elegance. These tiny devices, often no larger than a coin, rely on the energy stored in coiled springs to keep time without batteries or electronics. Their intricate gears and springs showcase a craftsmanship that’s both artistic and functional, inspiring contemporary engineers to rethink how we design devices that are reliable, energy-efficient, and long-lasting.

Mechanical toys, once a staple of childhood amusement, also highlight the versatility of spring technology. These toys harness the power of wound-up springs to animate figures, animals, or vehicles with minimal complexity. Their appeal lies in their simplicity and the sense of wonder they evoke—there’s no need for batteries or electronic components; just a twist of the key or a pull of a string activates the toy’s movement. Today, this same principle influences the development of more sophisticated mechanical devices, emphasizing the importance of mechanical energy transfer over digital reliance. The enduring charm of mechanical toys underscores that, even in an age dominated by electronics, spring-powered mechanisms still hold a special place in both entertainment and engineering.

Mechanical toys showcase spring technology’s simplicity and wonder, blending entertainment with engineering ingenuity.

Looking ahead, the potential of traditional springs extends beyond nostalgic relics. Miniature timepieces are pushing the boundaries of precision engineering, integrating advanced materials and micro-mechanical systems to improve accuracy and longevity. Researchers are exploring how these tiny springs can be part of wearable technology, medical devices, or even autonomous sensors. The core idea remains the same: storing and releasing mechanical energy in a controlled manner to perform useful functions. This approach offers advantages like independence from power sources, resistance to electromagnetic interference, and a level of robustness that digital systems often lack.

In essence, the humble spring is proving to be more than just a nostalgic relic or a component of vintage toys. It’s a fundamental element in a new wave of technology that values mechanical simplicity, energy efficiency, and durability. Whether in miniature timepieces that keep impeccable time or in mechanical toys that delight generations, springs continue to demonstrate their timeless relevance. They remind us that sometimes, the most straightforward solutions are the most innovative—especially when they’re powered by the timeless resilience of a well-wound spring.

Frequently Asked Questions

How Do Spring-Powered Devices Compare to Modern Electronic Counterparts?

Spring-powered devices are generally less energy-efficient than modern electronic counterparts, as they rely on stored mechanical energy that gradually releases. You’ll find they require more maintenance because springs can wear out or lose tension over time, unlike electronics that need less frequent upkeep. However, spring-powered devices can operate independently of electricity, making them reliable in specific situations. Overall, electronics surpass them in efficiency, longevity, and ease of maintenance.

What Are the Main Challenges in Designing Spring-Powered Machinery?

You might think spring-powered machinery is simple, but designing it is tricky. Material fatigue weakens springs over time, risking failure, while optimizing energy efficiency challenges you to balance stored energy with minimal wear. You need to select durable materials and precise mechanisms, ensuring consistent performance. Managing these issues requires careful engineering, patience, and innovation, making spring-powered devices surprisingly complex despite their apparent simplicity.

Can Spring-Powered Technology Be Scaled for Large Industrial Applications?

You can scale spring-powered technology for large industrial applications, but you face significant scaling limitations and questions about industrial feasibility. While springs can store substantial energy, managing that energy efficiently at larger sizes becomes complex. You need to contemplate material strength, wear and tear, and maintenance challenges. These factors make it difficult to implement spring-powered systems on a massive scale, limiting their practicality for extensive industrial use.

How Long Can a Typical Spring-Powered Device Operate Without Rewinding?

Imagine you’re a Victorian engineer in a steampunk universe; a typical spring-powered device can operate for about 8 to 24 hours without rewinding. The duration depends on spring tension and winding frequency—more tension means more power but quicker unwinding. Regular winding is essential to maintain consistent operation, as the device’s energy reserves diminish with use. So, plan your winding schedule accordingly to keep things running smoothly.

What Materials Are Best Suited for Durable, Long-Lasting Springs?

You should choose spring materials with excellent fatigue resistance, like high-carbon steel or alloy steels, for durability and longevity. These materials withstand repeated winding and unwinding without losing strength. Spring material selection is vital for ensuring your device operates reliably over time. Opt for alloys specifically designed for fatigue resistance, such as music wire or stainless steel, to maximize the spring’s lifespan and maintain consistent performance.

Conclusion

Think of spring-powered devices as the hidden springs of innovation, quietly driving progress forward. Just like a well-wound watch, these mechanisms store energy and release it precisely when needed, proving that ingenuity isn’t always about the loudest engines. As you explore this world beyond steam engines, remember that sometimes, the smallest, most intricate parts can power the biggest advancements. Keep winding your curiosity; the future of tech is springing to life in unexpected ways.